This is a new section that I’m adding to ModBlog in which we talk to some of the best artists around the world about the nuances of the business of being not just good at what you do, but great. In this first column, we’ll be talking about jewelry — does it really make a difference if you’re using generic “316LVM” versus something that’s “ASTM-spec”? Is titanium really better? Is threading important? What if someone brings in their own jewelry?

I thought this would be a good one to start with, given the recent example of the kid who thought chain links would make acceptable jewelry!

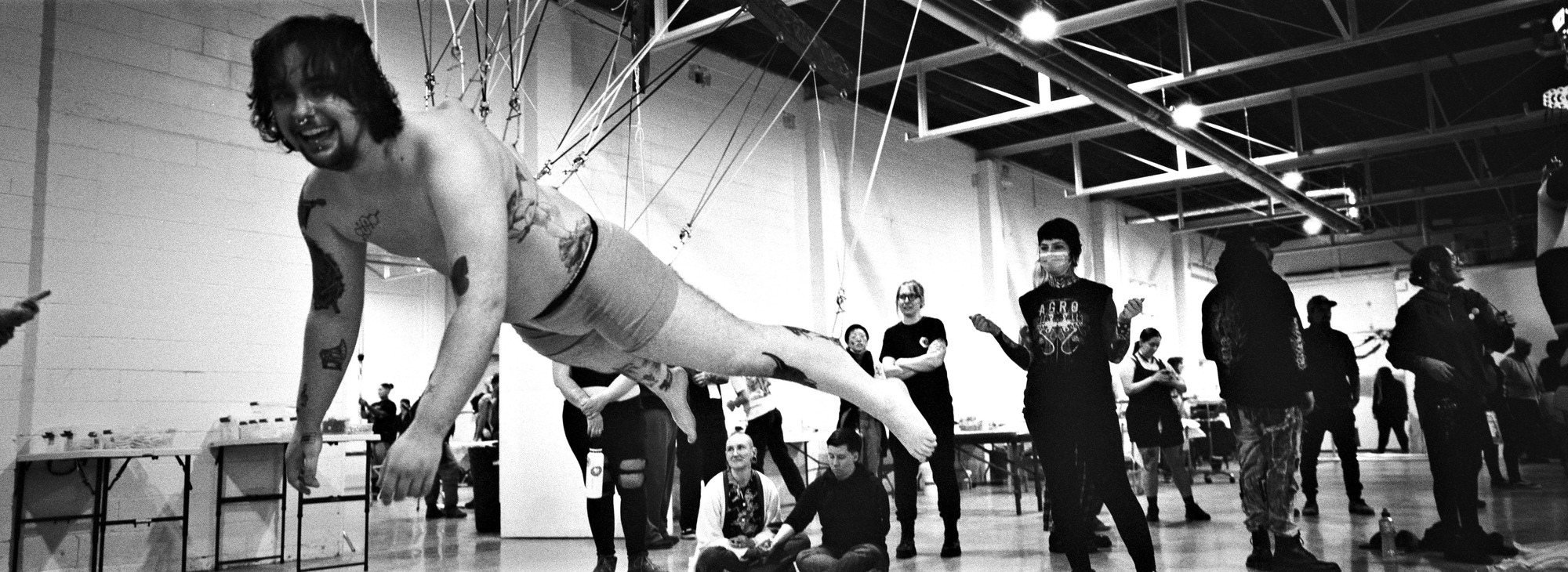

In today’s column, commentary comes from (shown left to right below), Patrick Bartholomew (a mostly retired piercing pioneer who you may know from the London Piercing Clinic, and can be found at iam:PatrickB), Tom Brazda (iam:TomBrazda, TomBrazda.com, former owner and head piercer of Stainless Studios, now doing research and development into new body modification technologies and aftercare at BodyArt Pro), “Moddoctor” (iam:Moddoctor (a practising physician in the United States that is primarily a cosmetic surgeon but who also does piercing), and Leo Ziebol (iam:5point, co-owner of 5pointstudios)

PATRICK BARTHOLOMEW:

After fighting a running battle with rejection from allergies to stainless steel jewellery I finally stopped using it in fresh piercings on the first of January, 1992. I changed to titanium, and I have stayed with it ever since. With the steel I would have an average problem factor with rejection as high as twenty percent of all piercings, either minor “walking” out of alignment, or full rejection — with the Titanium it reduced to less than one piercing in four thousand. That was good enough for me. I also insist on supplying the initial jewellery.

TOM BRAZDA:

ASTM complient materials are designed to survive inside the human body and also release little to no toxic elements. These standards are changed as new information comes to light. If it does not comply with these standards then its considered a “commercial” grade material.

But material alone does not make a good piece of jewelry — you need a good smooth surface finish since the surface of the jewelry is what will be in contact with the healing tissue. If it’s not truly smooth it will increase scarring during the healing process by abrading the tissue as it moves around. The balls on the jewelry whether, it’s a barbell or captive need to be held on well and not come loose easily. The edges of the ring or barbell need to be rounded and smooth as well so that there is no sharp edge being pushed against the tissue.

The internal/external issue is a tough one since I’ve seen crappily made internals and well thought out externals. Whats important is what is in contact with the tissue during a jewelry insertion. Any sharp edge will cause damage.

Titanium is better in the sense that the tissue growth around it is not as dense as the tissue that forms around stainless, and since it’s lighter it’s better in heavier gauge piercings. But there are people out there that are sensitive to titanium, just like there are people sensitive to nickel. What makes the biggest difference is how “passive” the surface layer of the jewelry is. This can be achieved well in both stainless and titanium with proper processing.

Finally, if a customer brings in a piece of jewelry, unless I know who made the jewelry, I won’t use it. Most of the time its not even an appropriate size to do that persons piercing. People don’t come in standard sizes so “standard” sized jewelry doesn’t work!

MODDOCTOR:

It’s pretty remarkable how little difference jewelry material often makes. People with no metal sensitivities can heal with anything it seems. You could pierce those people with a paperclip (not really!) and they would do fine. Other people, though, just refuse to heal with stainless jewelry and I have found that changing to titanium resolves those problems. That said, jewelry quality makes a big difference across the board. Cheap jewelry seems like it sticks in a healing piercing, which may be the result of less than smooth polished surfaces.

As for internal versus externally threaded, I definitely prefer using internally threaded. It’s easier to pass through a fresh piercing and jewelry changes are less traumatic even in a well healed hole.

LEO ZIEBOL:

When it comes to jewelry, I don’t know much about how different metal affect the body on a cellular level but I do know that I want to do everything I can to help that piercing heal as easily as possible. I have seen a lot of problems associated directly to poor jewelry. I’ve also seen some of the most god-aweful pieces of reconstituted tin can heal excellently. For me, using quality jewelry is another way that I minimize the chance factor. I will never eliminate it but I will do my best to keep it as low as possible.

It is rare that I will use jewelry brought in by a client. We have one other shop in our area that uses ASTM internals and I would gladly use a piece that was brought in from there as long as it wasn’t damaged or of improper size for that client. If I don’t know where it came from or what company made it, I won’t use it.

So… Four experienced piercers, one a piercing pioneer, and one a doctor, all appear to be in general agreement — not only is it important to seek out not only jewelry made of high quality materials that are inherently biocompatible, but that the finish of the jewelry is of equal importance (so even if jewelry is a good material, if it’s not well manufactured, it will still complicate thing). All quality studios should be able to tell you exactly what materials they are putting in you and who manufactured them. You may pay a little more, but really, would you rather pay $25 for a piercing that’s going to be irritated, take longer to heal, and potentially reject, or $50 for one with a solid shot of lasting a lifetime?

In the next installment of this column we’ll be talking about items a good studio should have, that too few people have gone to the effort to obtain.

Comments

110 responses to “Is Body Jewelry Quality Important?”

Tom – is there a known reason why the tissue that heals around Ti tends to be less dense than that which heals around steel?

Tom – is there a known reason why the tissue that heals around Ti tends to be less dense than that which heals around steel?

And I thought I was a freak for having my eyebrow react badly to stainless steel =) A great idea, Shannon.

And I thought I was a freak for having my eyebrow react badly to stainless steel =) A great idea, Shannon.

Nice piece 🙂

Always happy to see quality jewellery promoted – and especially to see the onus evenly weighted on manufacture & finish!!

Personally I’m surprised step-down threading isn’t more popular. It strikes me as easier to manufacture than internal, would locate securely behind the needle, and still keeps the threading away from the tissue. Feel free to correct me, of course.

Nice piece 🙂

Always happy to see quality jewellery promoted – and especially to see the onus evenly weighted on manufacture & finish!!

Personally I’m surprised step-down threading isn’t more popular. It strikes me as easier to manufacture than internal, would locate securely behind the needle, and still keeps the threading away from the tissue. Feel free to correct me, of course.

Toast – I’m guessing step-down you mean external threading.

Though, I’m no where near a professional, personally I’ve found that, or so it seemed, that all of the externally threaded jewelry I’ve seen weren’t that great of quality. And though you can hide the threading inside the needle to not rip anything after the initial pierce, removing it or changing jewelry afterwards could be a damaging factor, as the threading can then rip the tissue as it is not hidden in the needle.

And I’ve also found the beads tends to come off far easier with externally threaded.

But this is all just my opinion/thoughts.

Toast – I’m guessing step-down you mean external threading.

Though, I’m no where near a professional, personally I’ve found that, or so it seemed, that all of the externally threaded jewelry I’ve seen weren’t that great of quality. And though you can hide the threading inside the needle to not rip anything after the initial pierce, removing it or changing jewelry afterwards could be a damaging factor, as the threading can then rip the tissue as it is not hidden in the needle.

And I’ve also found the beads tends to come off far easier with externally threaded.

But this is all just my opinion/thoughts.

There are two “issues” with stepdown threading.

On one hand, even though it’s stepped down, there IS still threading there, and it does still have a higher potential to cause damage than internal. Granted, that potential is pretty minimal (and not likely to happen during the initial piercing) compared to standard external but it’s still not totally eliminated like it is with external.

Second (and probably a bigger factor), very few companies produce step-down out of good materials and that is well-made, and it’s not compatable with most other quality jewelry because most other quality jewelry is internal. It’s simply a standardization issue. If there are 10 companies making good quality jewelry, and 8 of them are doing internal and 2 are doing step-down, it definitely puts a burden on the two who aren’t doing internal.

Excellent to hear the opinions of all four people, and I think this is a great topic! I couldn’t agree more with most of the opinions.

I’m surprised no one mentioned potential corrosion issues with steel when it’s in contact with blood and body fluids. To me, that’s the defining bit of information that spurred my switch to using solely titanium jewelry.

There are two “issues” with stepdown threading.

On one hand, even though it’s stepped down, there IS still threading there, and it does still have a higher potential to cause damage than internal. Granted, that potential is pretty minimal (and not likely to happen during the initial piercing) compared to standard external but it’s still not totally eliminated like it is with external.

Second (and probably a bigger factor), very few companies produce step-down out of good materials and that is well-made, and it’s not compatable with most other quality jewelry because most other quality jewelry is internal. It’s simply a standardization issue. If there are 10 companies making good quality jewelry, and 8 of them are doing internal and 2 are doing step-down, it definitely puts a burden on the two who aren’t doing internal.

Excellent to hear the opinions of all four people, and I think this is a great topic! I couldn’t agree more with most of the opinions.

I’m surprised no one mentioned potential corrosion issues with steel when it’s in contact with blood and body fluids. To me, that’s the defining bit of information that spurred my switch to using solely titanium jewelry.

Hmmm… I’m glad I mentioned piercing education after seeing the kid with chain links pushed into his face.

Hmmm… I’m glad I mentioned piercing education after seeing the kid with chain links pushed into his face.

I have to say my opinion on higher quality jewelry is definitly important to me and others I know that are pierced and will be pierced in the future. The kid who pierced his face with the fence chain links is a complete idiot, if he thought that was going to heal in any healthy sort of way, or at all he is a moron!

I have to say my opinion on higher quality jewelry is definitly important to me and others I know that are pierced and will be pierced in the future. The kid who pierced his face with the fence chain links is a complete idiot, if he thought that was going to heal in any healthy sort of way, or at all he is a moron!

I have been to a number of “good” piercing shops on the West Coast (of the US). I have found an unwillingness for shops to carry high-polish titanium in implant grade because “it looks just like steel and no one buys it.” I would buy it! Instead, I have been forced to purchase titanium online from reputable sources which can take 4+ weeks to arrive. This is a frustration I have been unable to overcome.

How can the buyer/customer be assured that what they are puchasing is titanium? To the best of my knowledge, there is no required standard markings on jewelry to indicate whether they are steel or titanium. With gold and sterling silver rings, necklaces, etc., there is a stamp that will read 14k or .995/.999 indicating the grade of gold or silver.

I understand that such a marking on body jewelry would be complicated, expensive, and potentially time-consuming for manufacturers. One problem being, that “stamp” reading Ti would have to be somewhere where it wouldn’t interfere with the piercing. One such place could be just inside the internally threaded bar, before the threads begin. Threaded balls would have to have longer threaded shafts to accomodate the threading beginning farther into the barbell.

The complications and cost make this near impossible.

I still wish there was a way to be assured of the material, quality, and manufacturer from the CONSUMER end of body modification. I can’t tell you how many times I’ve heard a piercer at a random shop say, “316LVM, what’s that?” Or I’ve asked, “is this titanium or steel?” only to receive the answer, “titanium, wait, no, steel; yeah, steel.”

The only assurance I’ve identified is to order from the manufacturer and wait for the package to arrive.

I have been to a number of “good” piercing shops on the West Coast (of the US). I have found an unwillingness for shops to carry high-polish titanium in implant grade because “it looks just like steel and no one buys it.” I would buy it! Instead, I have been forced to purchase titanium online from reputable sources which can take 4+ weeks to arrive. This is a frustration I have been unable to overcome.

How can the buyer/customer be assured that what they are puchasing is titanium? To the best of my knowledge, there is no required standard markings on jewelry to indicate whether they are steel or titanium. With gold and sterling silver rings, necklaces, etc., there is a stamp that will read 14k or .995/.999 indicating the grade of gold or silver.

I understand that such a marking on body jewelry would be complicated, expensive, and potentially time-consuming for manufacturers. One problem being, that “stamp” reading Ti would have to be somewhere where it wouldn’t interfere with the piercing. One such place could be just inside the internally threaded bar, before the threads begin. Threaded balls would have to have longer threaded shafts to accomodate the threading beginning farther into the barbell.

The complications and cost make this near impossible.

I still wish there was a way to be assured of the material, quality, and manufacturer from the CONSUMER end of body modification. I can’t tell you how many times I’ve heard a piercer at a random shop say, “316LVM, what’s that?” Or I’ve asked, “is this titanium or steel?” only to receive the answer, “titanium, wait, no, steel; yeah, steel.”

The only assurance I’ve identified is to order from the manufacturer and wait for the package to arrive.

the studies showing this denser tissue never addressed the reason but i tend to feel thats its due to how much the body senses the material and how much it feels it needs to protect itself from it. what causes this reaction is what is leeching out of the material. if its a minerla that the body needs, it does’nt worry about it but our body does’nt need minerals like nickel .

these studies that i read were from at least 12 years back and were biopsies done on older implants so what is astm standard today is better then what was standard back then.

the studies showing this denser tissue never addressed the reason but i tend to feel thats its due to how much the body senses the material and how much it feels it needs to protect itself from it. what causes this reaction is what is leeching out of the material. if its a minerla that the body needs, it does’nt worry about it but our body does’nt need minerals like nickel .

these studies that i read were from at least 12 years back and were biopsies done on older implants so what is astm standard today is better then what was standard back then.

titanium at room temperature feels plastic to the touch since it does’nt conduct heat very well while steel will feel cold to the touch since it does

titanium at room temperature feels plastic to the touch since it does’nt conduct heat very well while steel will feel cold to the touch since it does

Tiffany: Very good points. Without an anodizer, or metal certificates it’s next to impossible to tell the difference between titanium and steel as far as I know for smaller pieces. Obviously, for larger-gauge pieces the weight will be an instant indicator, but the weight difference in a 14g or smaller piece probably isn’t going to be noticable short of carrying a scale with you and comparing a titanium and a steel piece side-by-side.

Tiffany: Very good points. Without an anodizer, or metal certificates it’s next to impossible to tell the difference between titanium and steel as far as I know for smaller pieces. Obviously, for larger-gauge pieces the weight will be an instant indicator, but the weight difference in a 14g or smaller piece probably isn’t going to be noticable short of carrying a scale with you and comparing a titanium and a steel piece side-by-side.

potential corrosion issues with stainless are overcome with proper passivation of the surface of the jewelry. these corrosion issues are greater inside the body then in a piercing since the implant is not exposed to as much oxygen as it would in a piericng. the passive layer on all metals is an oxide. these layers can repair themselves in an oxygenated enviroment

potential corrosion issues with stainless are overcome with proper passivation of the surface of the jewelry. these corrosion issues are greater inside the body then in a piercing since the implant is not exposed to as much oxygen as it would in a piericng. the passive layer on all metals is an oxide. these layers can repair themselves in an oxygenated enviroment

Aside from the actual content of this post, I just wanna say I love the idea of posts like this!! Better education=healthier and more successful mods. YAY!

Aside from the actual content of this post, I just wanna say I love the idea of posts like this!! Better education=healthier and more successful mods. YAY!

Thumbs up for a section like this.

Thumbs up for a section like this.

This is fascinating and I look forward to further installments in this section!

This is fascinating and I look forward to further installments in this section!

Great thread idea. As a piercer, I feel adimant about ASTM compliant materials.

While we all know that countless people have used 316L, 316 or even sterling silver from claire’s and have still healed fine, I still can’t imagine why anyone would want to save a few bucks regarding something that they hope to keep for years to come.

I don’t hear enough people ask the questions about nickel content in regards to gold jewelry. It is my understanding (and please correct me if I’m wrong) that since gold is an alloy, 14kt holds 58% gold and the remaining 42% is usually made of silver and copper. Copper usually has a good amount of nickel in it. Whereas a great alternative is gold that is paladium based rather than copper, making it extremely low if not free of nickel.

As for external threads, again, why save a few bucks on something you hope to keep for years? Cheaper jewelry is cheaper for a reason, mostly in the manufacturing of the piece. Internal is more pricey, but another important factor is the polishing finish. For all the things that can be automated or downgraded for the sake of cost, I understand that you still need a person on hand to give the jewelry a proper shine. With that and metal composition in mind, those are the corners that are cut with cheaper jewelry. Jewelry that hasn’t been properly polished has a much less attractive finish. It also usually has a larger degee of residue of the polishing compound left on the jewelry (such as in the microscopic crevices). Althought that is something an ultrasonic should aleviate prior to being autoclaved.

I’m a bit surprised, I expected more posts of people saying they really don’t care if it is ASTM compliant. I’m glad to have been proven mistaken!

Am I wrong on anything I’ve written? If so, correct me (with logical and scientifically based argument). That is how we can all learn more and be better educated.

Great thread idea. As a piercer, I feel adimant about ASTM compliant materials.

While we all know that countless people have used 316L, 316 or even sterling silver from claire’s and have still healed fine, I still can’t imagine why anyone would want to save a few bucks regarding something that they hope to keep for years to come.

I don’t hear enough people ask the questions about nickel content in regards to gold jewelry. It is my understanding (and please correct me if I’m wrong) that since gold is an alloy, 14kt holds 58% gold and the remaining 42% is usually made of silver and copper. Copper usually has a good amount of nickel in it. Whereas a great alternative is gold that is paladium based rather than copper, making it extremely low if not free of nickel.

As for external threads, again, why save a few bucks on something you hope to keep for years? Cheaper jewelry is cheaper for a reason, mostly in the manufacturing of the piece. Internal is more pricey, but another important factor is the polishing finish. For all the things that can be automated or downgraded for the sake of cost, I understand that you still need a person on hand to give the jewelry a proper shine. With that and metal composition in mind, those are the corners that are cut with cheaper jewelry. Jewelry that hasn’t been properly polished has a much less attractive finish. It also usually has a larger degee of residue of the polishing compound left on the jewelry (such as in the microscopic crevices). Althought that is something an ultrasonic should aleviate prior to being autoclaved.

I’m a bit surprised, I expected more posts of people saying they really don’t care if it is ASTM compliant. I’m glad to have been proven mistaken!

Am I wrong on anything I’ve written? If so, correct me (with logical and scientifically based argument). That is how we can all learn more and be better educated.

So glad to see these issues being made PUBLIC and not just discussed amongst ourselves in the learning forum,etc 😉

Tom hit it right on the head, as always. It’s not about Steel or Ti being better then the other, as there’s documented case of allergic reactions/sensitivities on both sides,etc.

Its about buying the jewelry from companies that manufacturer the jewelry well and produce consistent high quality product out of ASTM Compliant materials. It’s about making sure each shop has all the required documentation proving that what they are offering to the customer is ideal product.

Now sadly most clients just simply take for granted that we are all identical and Shop A and Shop B as well as Shop C all carry the same jewelry, and all piercers at those shops were trained the same…Sadly this is never accurate and true.

I’m really glad that these subjects are being touched on.

Also Tiffany you’re very accurate in saying that, which is a sad state of affairs when people you are going to, can’t tell the difference either.

However I do know of a company up here in Canada that actually stamps Ti actually on the beads of their products to help tell the difference,etc.

But personally I think its just a bit easier to seperate and process/sterilize jewelry in states, ie: Steel with Steel, Ti with Ti,etc. Then from there after processing the materials they should be put in seperately marked containers,etc. So no confusion can be made.

So glad to see these issues being made PUBLIC and not just discussed amongst ourselves in the learning forum,etc 😉

Tom hit it right on the head, as always. It’s not about Steel or Ti being better then the other, as there’s documented case of allergic reactions/sensitivities on both sides,etc.

Its about buying the jewelry from companies that manufacturer the jewelry well and produce consistent high quality product out of ASTM Compliant materials. It’s about making sure each shop has all the required documentation proving that what they are offering to the customer is ideal product.

Now sadly most clients just simply take for granted that we are all identical and Shop A and Shop B as well as Shop C all carry the same jewelry, and all piercers at those shops were trained the same…Sadly this is never accurate and true.

I’m really glad that these subjects are being touched on.

Also Tiffany you’re very accurate in saying that, which is a sad state of affairs when people you are going to, can’t tell the difference either.

However I do know of a company up here in Canada that actually stamps Ti actually on the beads of their products to help tell the difference,etc.

But personally I think its just a bit easier to seperate and process/sterilize jewelry in states, ie: Steel with Steel, Ti with Ti,etc. Then from there after processing the materials they should be put in seperately marked containers,etc. So no confusion can be made.

how do we feel about niobium. i have been wearing it exclusively in my ears simply because i like the look. i certainly assume that anything anatometal is top notch. just curious if anything knows how this metal compares to steel or titanium.

how do we feel about niobium. i have been wearing it exclusively in my ears simply because i like the look. i certainly assume that anything anatometal is top notch. just curious if anything knows how this metal compares to steel or titanium.

i LOVE this entry, totally. it’s really good to have this kind of information available for custommers and pople seeking a well done piercing procedure, to ensure the best piercing experience available.

i agree with my mates all….it’s really important to have high quality jewelry in a fresh piercing. i do not work with it, cos currency exchanges here in argentina make things pretty difficult, but i’m aware of the benefits of it, i’m struggling really hard to change things over here.

i can say this cos i’ve seen many strange things during the years working here with asian jewelry, that works but it’s definately not the best jewelry. i found with this jewelry really weird things…i have clients that i piercer all over their bodies with 316lvm, and i cannot pierce their mucous membranes with it, cos they develop foreign body caused granuloma, switch to titanium and problem gone.

i encourage all the piercers around the world to do their best effort to change to higher quality jewelry, as a sufferer of this, and as a constant growing and dedicated piercer for my clients, the community and myself i think it’s the ONLY way to go….though it’s hard on some countries like here…

i LOVE this entry, totally. it’s really good to have this kind of information available for custommers and pople seeking a well done piercing procedure, to ensure the best piercing experience available.

i agree with my mates all….it’s really important to have high quality jewelry in a fresh piercing. i do not work with it, cos currency exchanges here in argentina make things pretty difficult, but i’m aware of the benefits of it, i’m struggling really hard to change things over here.

i can say this cos i’ve seen many strange things during the years working here with asian jewelry, that works but it’s definately not the best jewelry. i found with this jewelry really weird things…i have clients that i piercer all over their bodies with 316lvm, and i cannot pierce their mucous membranes with it, cos they develop foreign body caused granuloma, switch to titanium and problem gone.

i encourage all the piercers around the world to do their best effort to change to higher quality jewelry, as a sufferer of this, and as a constant growing and dedicated piercer for my clients, the community and myself i think it’s the ONLY way to go….though it’s hard on some countries like here…

I had no idea that people were/could be allergic to stainless steal! My old piercer told me it was hypoallergenic.

I would definately pay $50 rather than $25 for better materials.

There are many stores where I live that carry very cheap looking jewelry that they claim is steel or titanium. I was going to buy some titanium barbells but they had no proof of their ingredients. I’m glad to have read this.

I had no idea that people were/could be allergic to stainless steal! My old piercer told me it was hypoallergenic.

I would definately pay $50 rather than $25 for better materials.

There are many stores where I live that carry very cheap looking jewelry that they claim is steel or titanium. I was going to buy some titanium barbells but they had no proof of their ingredients. I’m glad to have read this.

redneckzombi: I have gotten better at being able to tell titanium from steel, but that is from experience more than anything. I wear titanium rings on my fingers, titanium bracelets, and a titanium necklace. From seeing titanium in different shapes and polishes, I have gotten better at looking at a 12g piece of body jewelry and deciding whether I think it is titanium or not. But thinking and knowing are different, and I hate to take a gamble on whether or not the jewelry is going to cause problems with a piercing.

Yes, with larger pieces, weight is a good indicator. But is it a 4g straight barbell with steel balls? There is no way for me to know unless I put it in a piercing and hope my skin doesn’t come in contact with the balls. Guessing is not a good option. If I want a 4g high polish titanium straight barbell with titanium balls, I want to be assured that that is what I’m buying.

A certification issued by the manufacturer is something I had not thought of. That sounds like a less expensive change in protocol. I would even be willing to pay $5-10 more for a certificate.

redneckzombi: I have gotten better at being able to tell titanium from steel, but that is from experience more than anything. I wear titanium rings on my fingers, titanium bracelets, and a titanium necklace. From seeing titanium in different shapes and polishes, I have gotten better at looking at a 12g piece of body jewelry and deciding whether I think it is titanium or not. But thinking and knowing are different, and I hate to take a gamble on whether or not the jewelry is going to cause problems with a piercing.

Yes, with larger pieces, weight is a good indicator. But is it a 4g straight barbell with steel balls? There is no way for me to know unless I put it in a piercing and hope my skin doesn’t come in contact with the balls. Guessing is not a good option. If I want a 4g high polish titanium straight barbell with titanium balls, I want to be assured that that is what I’m buying.

A certification issued by the manufacturer is something I had not thought of. That sounds like a less expensive change in protocol. I would even be willing to pay $5-10 more for a certificate.

JasonZeh: Niobium is bio-compatible, much like PTFE, certain silicone tubing,etc. Its more Bio-Compatible then ASTM-Compliant Implant Grade materials.

again its understanding the client what their specific requirements…Some people require Ti, some Steel, others Niobium,etc.

And just like Tom said in the article its more about how the jewelry is made…All jewelry including niobium needs to have a VERY FLAWLESS polish/finish to it. Compared to many low quality manufacturers who just put their jewelry through a tumble polish cycle,etc.

JasonZeh: Niobium is bio-compatible, much like PTFE, certain silicone tubing,etc. Its more Bio-Compatible then ASTM-Compliant Implant Grade materials.

again its understanding the client what their specific requirements…Some people require Ti, some Steel, others Niobium,etc.

And just like Tom said in the article its more about how the jewelry is made…All jewelry including niobium needs to have a VERY FLAWLESS polish/finish to it. Compared to many low quality manufacturers who just put their jewelry through a tumble polish cycle,etc.

Is it possbile for someone to have a reaction to blackline? A friend of mine had blackline in his eyebrow and it went bad and started itching, when he changes it to Ti it all went and the piercing is still in today. At the time we looked it up online and from what we had read blackline was the best material you could put in a piercing and reactions to blackline were very rare…

Is it possbile for someone to have a reaction to blackline? A friend of mine had blackline in his eyebrow and it went bad and started itching, when he changes it to Ti it all went and the piercing is still in today. At the time we looked it up online and from what we had read blackline was the best material you could put in a piercing and reactions to blackline were very rare…

AJ never believe what you read online. Often many companies,etc PUSH products on you and make you think that if you don’t buy this specific product, you’re face will fall off.

Blackline to my knowledge isn’t ASTM Compliant material, but it DOES meet Bio-Compatibility test.

I snuck this from the head of Industrial Strength’s IAM page: http://www.machinedesign.com/ASP/viewSelectedArticle.asp?strArticleId=59958&strSite=MDSite&Screen=CURRENTISSUE&CatID=3

That article talks about Ceramic Biocompatibility,etc.

Again though AJ to answer your question, its much like Tom Brazda stated.

Some people need Steel, while others need Ti, while others need Niobium, and yes perhaps some need Blackline PVD jewelry. As well as just as some need these specific types, sometimes peope’s bodies do not like these types of materials.

Its all about how its processed,etc…For example I’d rather buy PVD Coated jewelry from Industrial Strength, then say a company that is selling the jewelry for $0.99.

This type of information should be easily distributed to both professionals as well as clients, so we ALL know better…The only bad thing is that some people in the industry have lower ethics then others, and are always willing to dip lower down and pay less regardless if the quality is less.

AJ never believe what you read online. Often many companies,etc PUSH products on you and make you think that if you don’t buy this specific product, you’re face will fall off.

Blackline to my knowledge isn’t ASTM Compliant material, but it DOES meet Bio-Compatibility test.

I snuck this from the head of Industrial Strength’s IAM page: http://www.machinedesign.com/ASP/viewSelectedArticle.asp?strArticleId=59958&strSite=MDSite&Screen=CURRENTISSUE&CatID=3

That article talks about Ceramic Biocompatibility,etc.

Again though AJ to answer your question, its much like Tom Brazda stated.

Some people need Steel, while others need Ti, while others need Niobium, and yes perhaps some need Blackline PVD jewelry. As well as just as some need these specific types, sometimes peope’s bodies do not like these types of materials.

Its all about how its processed,etc…For example I’d rather buy PVD Coated jewelry from Industrial Strength, then say a company that is selling the jewelry for $0.99.

This type of information should be easily distributed to both professionals as well as clients, so we ALL know better…The only bad thing is that some people in the industry have lower ethics then others, and are always willing to dip lower down and pay less regardless if the quality is less.

AJ: isn’t blackline just anodized stainless? Not truly titanium? If it is stainless then nickel sensitivity is absolutely possible.

AJ: isn’t blackline just anodized stainless? Not truly titanium? If it is stainless then nickel sensitivity is absolutely possible.